Why?

Firstly, let's cover how an electric fence works. The pulse leaves the "+" terminal of the fence energizer and enters the conductors. An animal touches the electrified conductor, creating a path, for the pulse, to the ground. The pulse travels through the ground/soil to the ground rod, where it enters the energizer via the negative terminal.

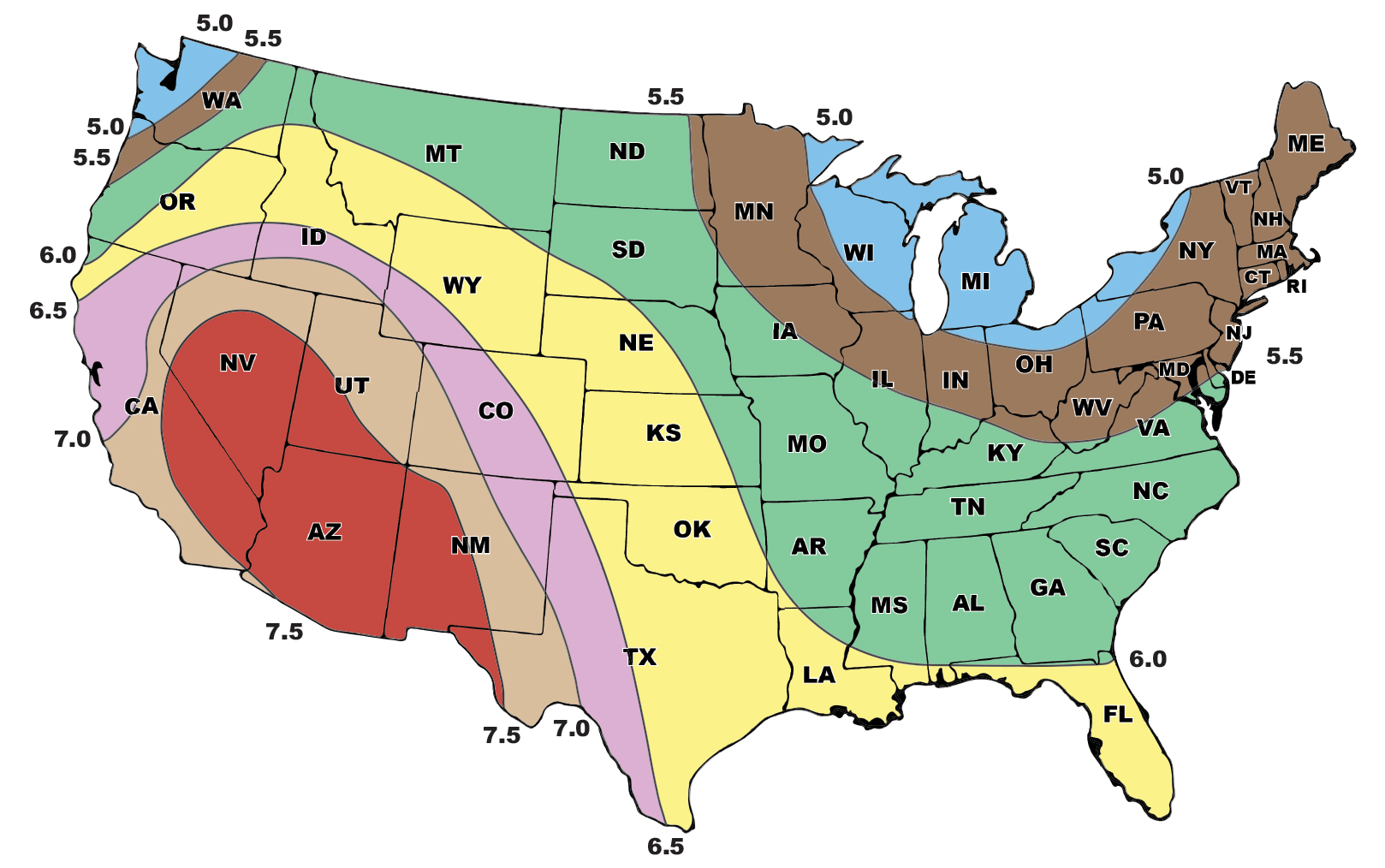

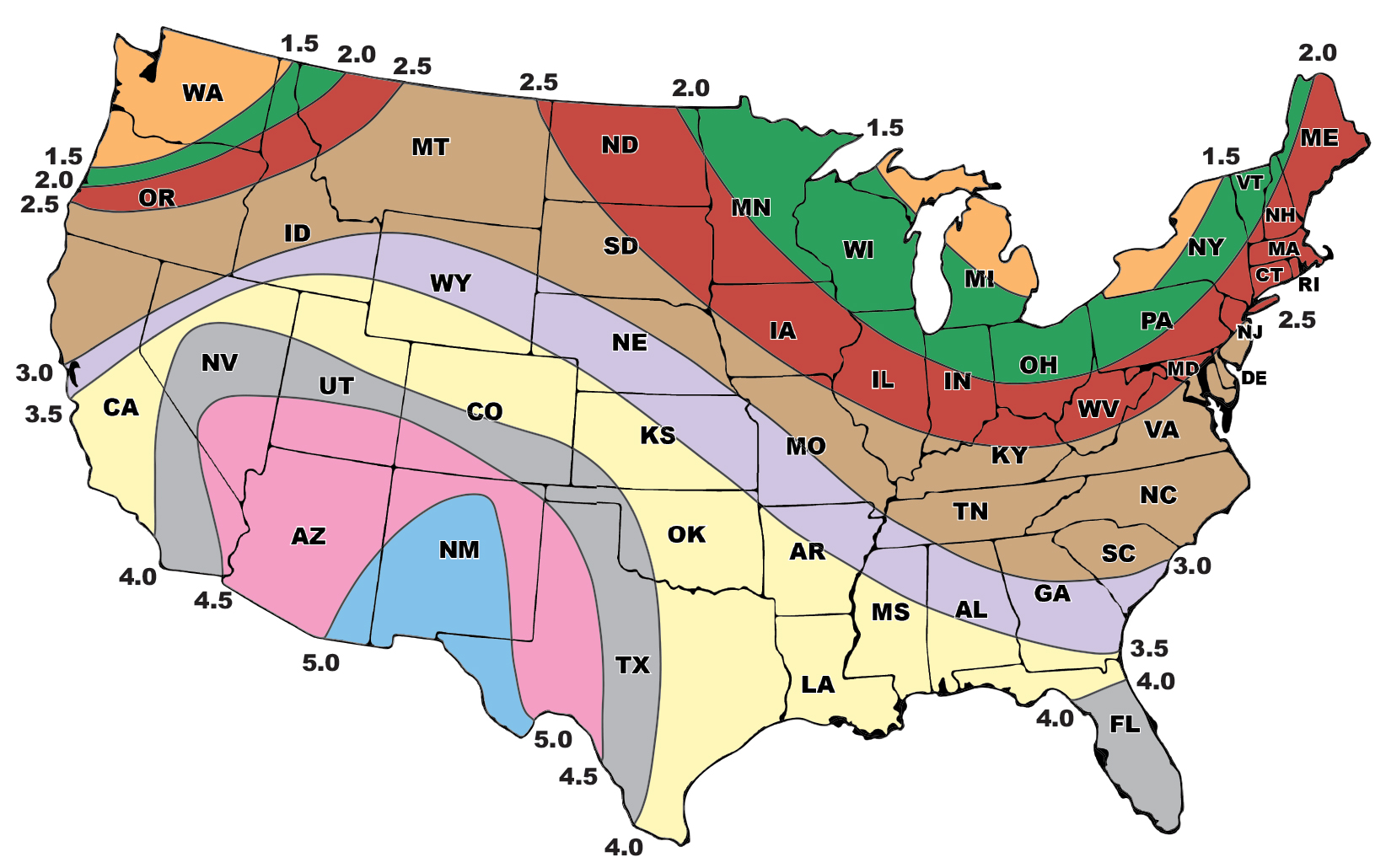

The key for this type of circuit is the soil. For the above system to work, the soil must be moist. The moisture reduces resistance against the pulse traveling to the ground rod.

When soils are dry, the resistance against the pulse is increased. This applies to rocky and sandy soils as well.

What's the workaround? There are two basic options:

- Increase the conductivity of the ground field

- Install as Positive/Negative Fence

Increasing conductivity

This is accomplished by either adding additional ground rods to the ground-field or moistening the area around the fence and ground rods.Adding ground rods puts more metal into the soil, acting as an attractant to the pulse. The more attractive the ground-system is to the energizer's pulse, the better able it can direct the pulse back to the energizer. However, if the soils are too dry (resistant) the pulse will not be able to overcome the lack of moisture.

By moistening the ground field or fence line, you are eliminating some of the resistance in the fence circuit. Watering the fence line is practical for short runs, not large paddocks and perimeters. Watering the ground field only reduces resistance in one location.

Pos/Neg

If watering is impractical, a Positive/Negative fence is recommended. A Pos/Neg fence is installed so half of its strands are connected to the fence terminal. They alternate position with the second half, which are connected to the ground system. When an animal touches both a positive and negative strand, the most direct route for the pulse is out the "+" conductor, through the animal, into the "-" conductor which leads back to the negative terminal (via ground rod). This eliminates the need for moisture to aid the pulse in its travel through the soil. The drawback is an animal must touch both a "+ and "–" strand in order to receive a shock. Pos/Neg fences are very effective fences in dry areas.A third (not widely available) option is the wide impedance energizer. Compared to low impedance units, they are capable of pushing a pulse through a wider range of fence resistances (low to medium) without loss in pulse power. A 6 joule low impedance energizer has an output of .59 joules at 5000 ohms of resistance, a 2.3 joule wide impedance unit has an output of 1.24 joules at 5000 ohms. Low impedance units are far more common and tend to cost less than wide impedance units. If you are in a dry, rocky or sandy area, a wide impedance is well worth the added expense.